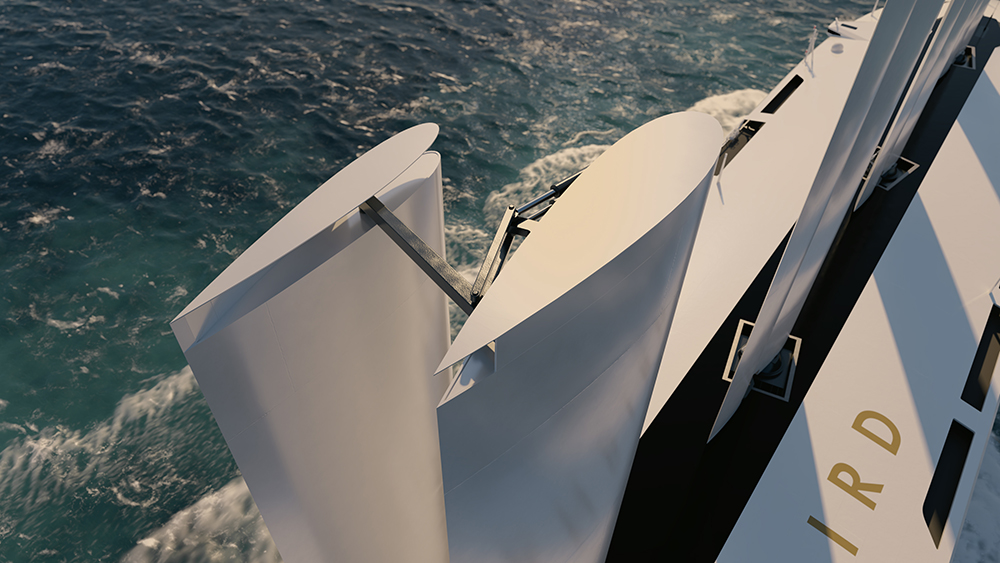

The new Oceanbird wing sail is pushing the edge even further. The wing consists of a main sail and a flap, optimizing the aerodynamics forces. It is half the size but shows the same performance as previous design, allowing a smaller footprint: both environmental and on deck.

To keep up with a tight time plan, and developing truly sustainable propulsion for the shipping industry, the engineers at Oceanbird needed to rethink previous design. Instead of a telescopic solution to allow the vessel to pass under bridges and reduce the power in hard weather, the new wing can be folded and tilted.

“The two-segment wing sail is aerodynamically optimized and provides a high propulsive power in relation to the wing area. The smaller segment, which we call flap, folds to the main sail before the whole wing is tilted, and therefore demanding less space on deck when it is not being used” says Mikael Razola, Technical Director at Oceanbird.

How is it more sustainable?

Sustainability is key in the Oceanbird concept. This new design are 40 meters high instead of 80 and therefore requires less material. A larger part of the wing sail is made of material that can be recycled. It is also more robust and long-lasting with less sensitive elements that can cause problems.

“We have visited suppliers, had a close dialogue with our potential customers and are now confident in that this is the way to move forward”, says Mikael Razola.

One wing saves 7-10 % on optimal routes

Each wing sail on an existing RoRo vessel will save around half a million-liter fuel (480,000 liter), equal to 3,000 barrels diesel a year on main trading routes.

On optimal routes in normal speed, one wing sail could reduce fuel consumption from main engine with 7-10 %. This means a saving of approx. 675,000 liters of diesel per year, which corresponds to approx. 1920 tonnes of CO2 per year.

The whole Oceanbird concept, including special designed hull, wing sails and speed/route recommendations, will reduce even more.

“We are proud over this design, which have the potential to revolutionize the shipping industry”, says Niclas Dahl, Managing Director at Oceanbird.

Reduced payback time

Another dimension of sustainability is financial. If we develop a product that drastically reduces emissions from shipping, but shipowners can’t justify the purchase, then we have not made an environmentally friendly product. Therefore, it was important to also reduce the payback time for the ship owners.

“For vessel owners who needs to comply with new emission legislation, for example CII, this solution can’t come soon enough. Not only we, but everyone in shipping, have a sense of urgency. This is a huge step closer in making the Oceanbird concept a reality,” says Niclas Dahl.

Next step

Oceanbird is evaluating different suppliers and will place an order for the first wing sail during the second half of 2022. Prototype testing will take place under 2023 and 2024. Meanwhile, Oceanbird is investigating solutions for placing wing sails on existing vessels in several shipping segments.

The first vessel with fully wind propulsion, is planned to sail in 2027.