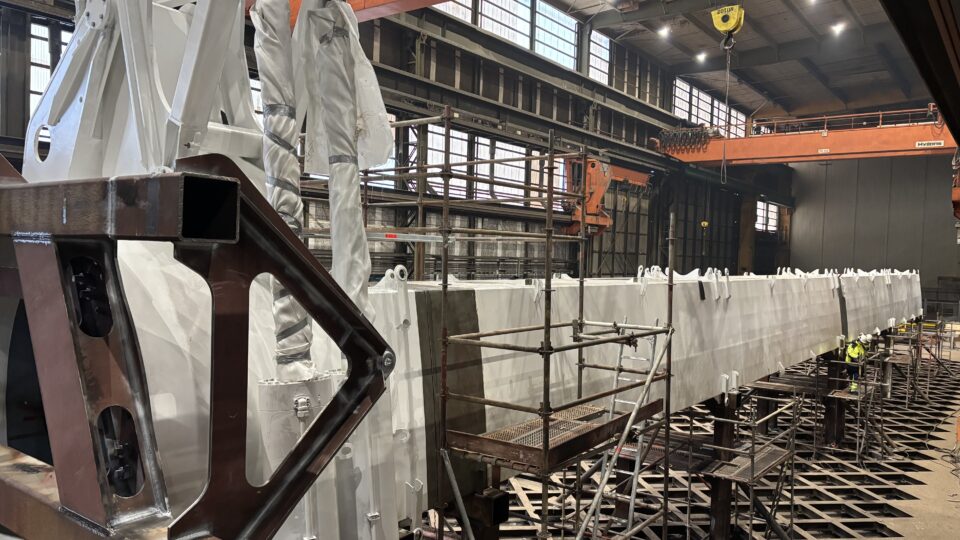

The steel mast inside the wing sail will transfer the forces from the wind into the ship to move it forward. All steel sections to the first wing prototype are now to be welded into a 40-meter-long mast at our test and assembly site in Southern Sweden.

“I once again realize how tall the wing will be” says Oceanbird Senior Product Manager Jonas Alván as he stands by the massive welding table in the assembly hall in Sweden´s largest shipyard Oresund DryDocks in Landskrona.

The mast is made of high-strength steel, which can be used in thinner dimensions than mild steel and still make the equipment stronger. It has been delivered to Landskrona in three sections from the production factory in Europe.

“To avoid a complicated transport that will affect entire cities, we have chosen to deliver the mast in parts and put it together here with the help of welders at the shipyard” says Jonas Alván.

Next step is to move the mast outside to the foundation, which is now standing by the sea. After being mounted on the foundation and connected to the hydraulic system, the testing of the mast can begin.

The aerodynamic shaped composites will soon arrive to the yard and will be installed on the mast later during the Spring.