The last piece of Oceanbird´s first wing sail has arrived at the yard in Landskrona – and it´s not a small piece. The 40-meter-long flap is made of glass fiber composites and recycled PET. Altogether, the wing sail consists of 370,000 recycled plastic bottles.

After been transported through Europe from the composite manufacturer to Southern Sweden, the 40-meter-long flap finally arrived at our test site in Oresund DryDock, Landskrona. The trailer with the wing sail and escort vehicles drove only during the nights in order not to disturb traffic.

“We had to remove road signs and close off roundabouts. It required meticulous planning from everyone involved” says Morgan Wallin, Mechanical Engineer at Oceanbird.

Flap optimizes aerodynamic forces

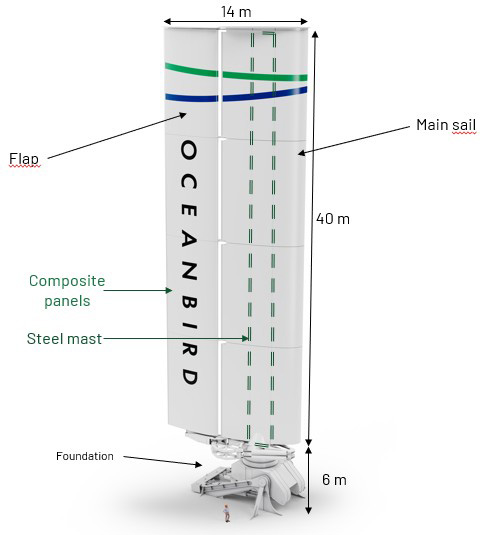

The wing consists of two segments: one main sail with a steel mast that transfers thrust to the vessel and one flap which creates camber. The camber optimizes how much thrust the wing harvests from the wind, like a traditional sail boat.

Sandwich construction

While the main sail was assembled at our test site in Landskrona, the flap came as a whole piece of 40*6 meter.

The material is a sandwich construction with thin layers of glass fiber and a core material of recycled PET bottles. One wing sail consists of 370,000 plastic bottles.

“If you have solid steel or solid composite, it is quite heavy. To avoid that, we add the core material of PET in the middle to create a distance so that we get higher bending stiffness”, says Ho-Ann Chen, Composite Design Engineer at Oceanbird.

Last step of assembly

During July, the flap will be installed to the main sail at the outdoor site by the water. After that, the final testing of the complete wing sail will take place until the official inauguration in the end of August.