After less than one year on a vessel, the Oceanbird Wing will have saved enough emissions to make up for its carbon footprint – the environmental return on investment (ROI). The first life cycle analysis shows where we need to improve, and has also led to increased awareness at the production facilities.

The parts to the first Oceanbird Wings are being manufactured right now, and all things produced of course have an impact on the environment. To get a better understanding of where the major environmental impacts occur and how to reduce them, Oceanbird have made a life cycle analysis on the Wing 560, mainly focusing on carbon emissions.

The calculation

Eleonora Strand from the consult agency Sigma Industry Development AB, has made the first life cycle analysis based on the design specifications under these circumstances:

- Cradle to grave during a 25-year period

- Wing installed on existing vessel during IMO route, which is an average of normal routes and not only ocean-going

- The vessel´s estimated time-at-sea (the wing in operation): 70%

Until we have the finished product, this is an estimate based on the wing design and material choices. Gathering data from Oceanbird´s suppliers have led to increased awareness at the manufacturers, all located in Europe.

“After our request, the suppliers have started to measure for example their energy consumption and amount of waste during production. They have also taken measures to improve their result, which will benefit their own as well as Oceanbird’s environmental footprint”, says Eleonora Strand.

The steel has the biggest impact

The life cycle analysis shows that one Oceanbird Wing 560 is releasing about 1,300 tones CO2eq during its lifetime. In this case it is assumed to be 25 years but it could be longer.

The life cycle analysis shows that one Oceanbird Wing 560 is releasing about 1,300 tones CO2eq during its lifetime. In this case it is assumed to be 25 years but it could be longer.

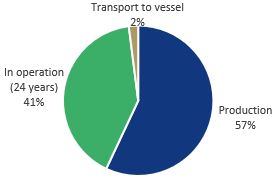

“The biggest environmental impact, 57%, comes from production. The only things that need electricity during operation is an electric engine for the hydraulic pump and automation system” says Eleonora Strand.

After that, the wing contributes to less CO2eq released from the vessel where it is installed. On car-carriers, it is estimated that the wing will save 1920 tonnes of CO2eq per year on optimal oceangoing routes, and 1,200 tonnes CO2eq on IMO route which is used in this calculation. Therefore, the wing would made up for the carbon emissions during production after eight months in operation. Then you need to add emissions for an estimated 24 years of operation. All together, the wing will have saved enough emissions to make up for its total carbon footprint after less than one year.

Keeping on the right path

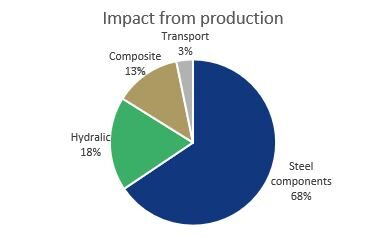

This first life cycle analysis confirmed many of our assumptions regarding which parts of the wing which have the most negative impact. The composites are partly made from recycled plastic. The mast inside the wing sail needs steel to be able to handle the heavy loads from the wind. Not surprisingly, it is the steel in the mast that has the greatest impact.

This first life cycle analysis confirmed many of our assumptions regarding which parts of the wing which have the most negative impact. The composites are partly made from recycled plastic. The mast inside the wing sail needs steel to be able to handle the heavy loads from the wind. Not surprisingly, it is the steel in the mast that has the greatest impact.

“Here we see a saving potential going forward from both weight, cost and environmental perspective. The steel industry is a major contributor to global emissions, but some manufacturers are also doing a lot to reduce their impact. We are using high strength steel, which is slightly better than regular. Our team is following the progress of carbon neutral steel production in close cooperation with these manufacturers” says Oceanbird´s Managing Director Niclas Dahl. “The progress towards recyclable composite, which is primarily driven by the wind power industry, is also very interesting.”

He sees a big advantage in doing a life cycle analysis already during the end of the design phase of Wing 560.

“We need to have the sustainability perspective with us from the very start to ensure that we don’t take the wrong path from the beginning. This is the first life cycle analysis of many to come. By doing this, we also pushed our suppliers in the right direction and that is a win in itself”.